Decoding OEM vs ODM Difference.

Navigating the Manufacturing Landscape:

Two commonly encountered terms in this realm are OEM and ODM, abbreviations for Original Equipment Manufacturer and Original Design Manufacturer, respectively.

While these terms may seem similar, they represent distinct approaches to product development and manufacturing.

*OEM: The Original Equipment Manufacturer

An OEM, or Original Equipment Manufacturer, is a company that designs and manufactures products according to the specifications provided by another company. The resulting products are then sold under the brand name of the company that commissioned the manufacturing, not the OEM itself.

OEMs typically possess extensive expertise in manufacturing processes and have the capacity to produce large volumes of products efficiently.

*ODM: The Original Design Manufacturer

An ODM, or Original Design Manufacturer, takes a more proactive role in the product development process. ODMs not only manufacture products but also handle the design and engineering aspects. They possess in-house design capabilities and offer pre-existing product designs to their clients, who can then customize these designs to suit their specific requirements.

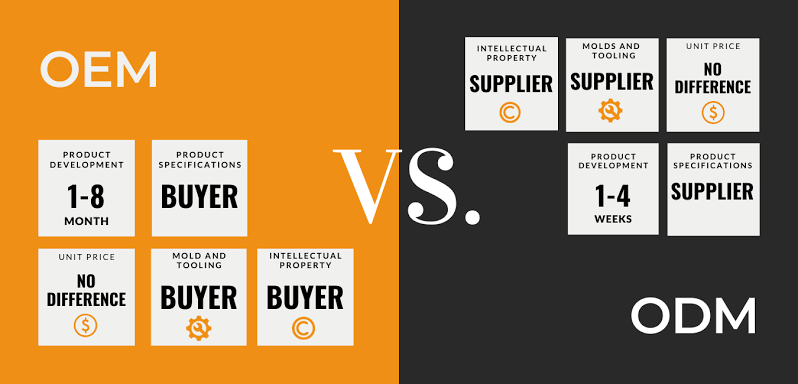

Key Differences between OEM and ODM

The fundamental distinction between OEM and ODM lies in the ownership of product design. With OEMs, the design is provided by the client, while ODMs take responsibility for the design themselves.

This difference leads to several implications:

*Design Control: OEMs offer greater control over product design, allowing companies to tailor products to their exact specifications. ODMs, on the other hand, provide pre-existing designs, which may limit customization options.

*Cost: OEMs typically charge higher prices due to the customized design and manufacturing process. ODMs, with their ready-made designs, often offer more cost-effective solutions.

*Time to Market: OEMs may require longer lead times due to the need for design collaboration and approval processes. ODMs, with their pre-existing designs, can often bring products to market more quickly.

*Innovation: OEMs may be better suited for companies seeking highly innovative or unique products. ODMs, with their focus on existing designs, may be more appropriate for companies seeking to quickly enter a market with a proven product.

Choosing the Right Model: OEM or ODM?

The decision between OEM and ODM hinges on several factors, including:

*Design Requirements: If you have specific design requirements or seek a highly customized product, an OEM may be the better choice. If you're open to using pre-existing designs, an ODM could be a more cost-effective option.

*Technical Expertise: If you lack in-house design expertise, an ODM can provide a complete solution. If you have strong design capabilities, an OEM can execute your vision.

*Time Constraints: If time to market is critical, an ODM's pre-existing designs can expedite the process. If you have ample time for design development, an OEM can provide a more tailored product.

*Budget: If budget is a primary concern, an ODM's ready-made designs may be more affordable. If you're willing to invest in a customized product, an OEM can deliver, albeit at a higher cost.

Conclusion

The choice between OEM and ODM is not a one-size-fits-all solution. Carefully consider your company's specific needs, design capabilities, time constraints, and budget to determine the most suitable approach for your product development and manufacturing goals.

FOLLOW @TechieGuyFOR MORE SUCH AMAZING CONTENT 🤙🤟.

Please sign in

Login and share